Machine Design

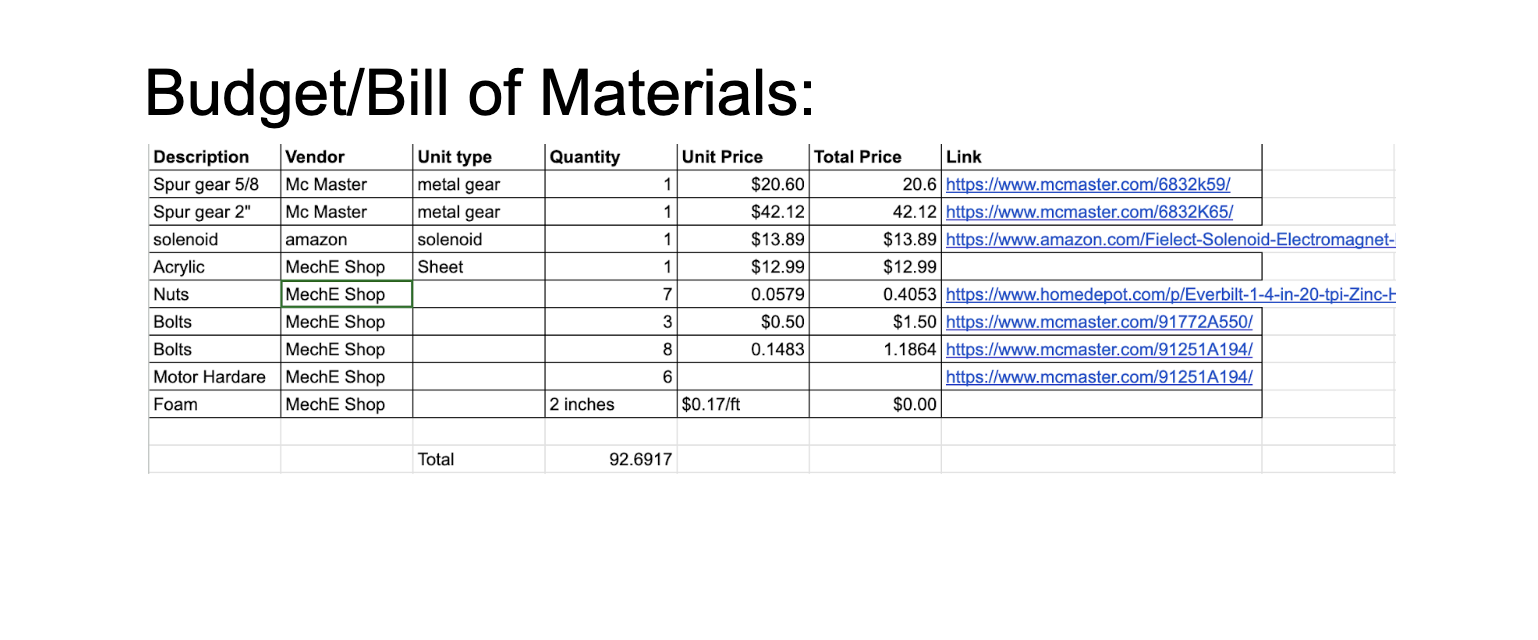

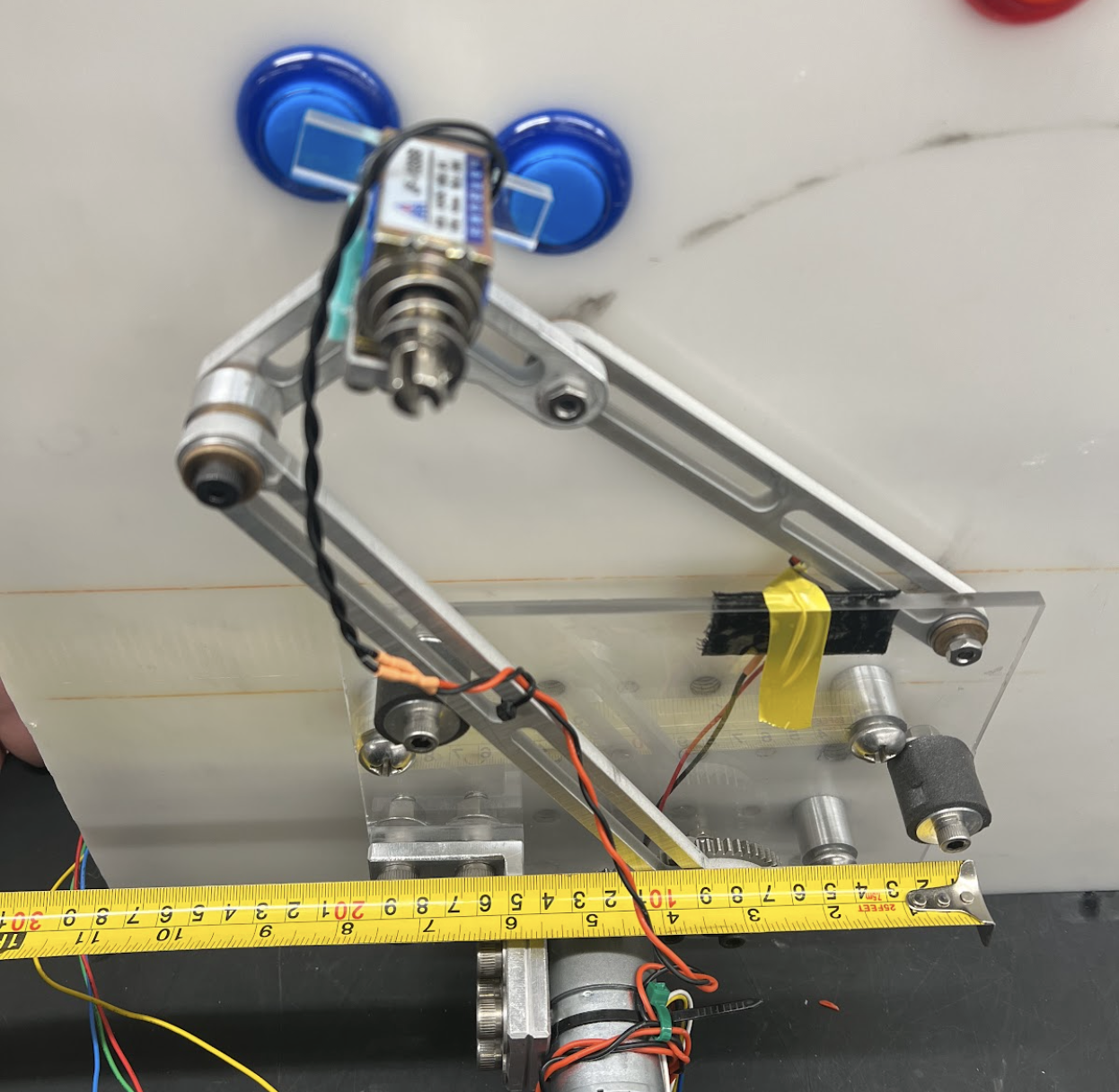

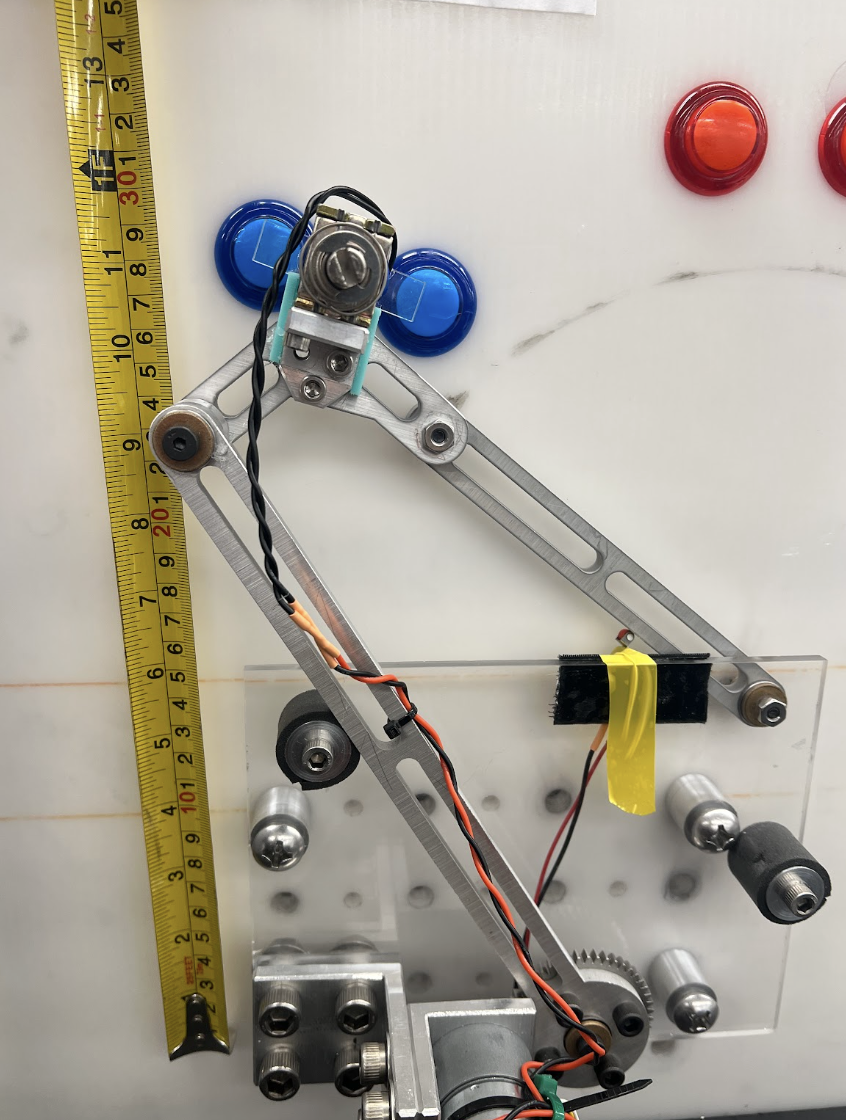

For this project my team designed, fabricated, and tested a four bar linkage capable of automatically pressing arcade buttons rapidly and accurately as possible within a one minute time constraint. The system identified color signals from an Arduino controlled playing field and moved to the correct button pair using a closed loop position control system.

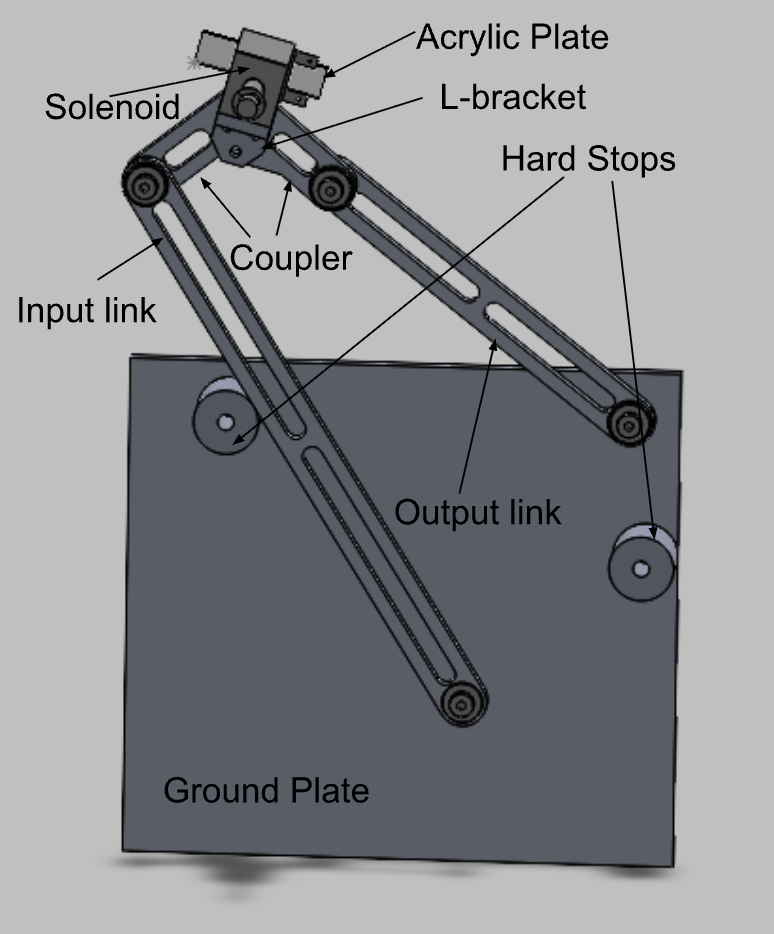

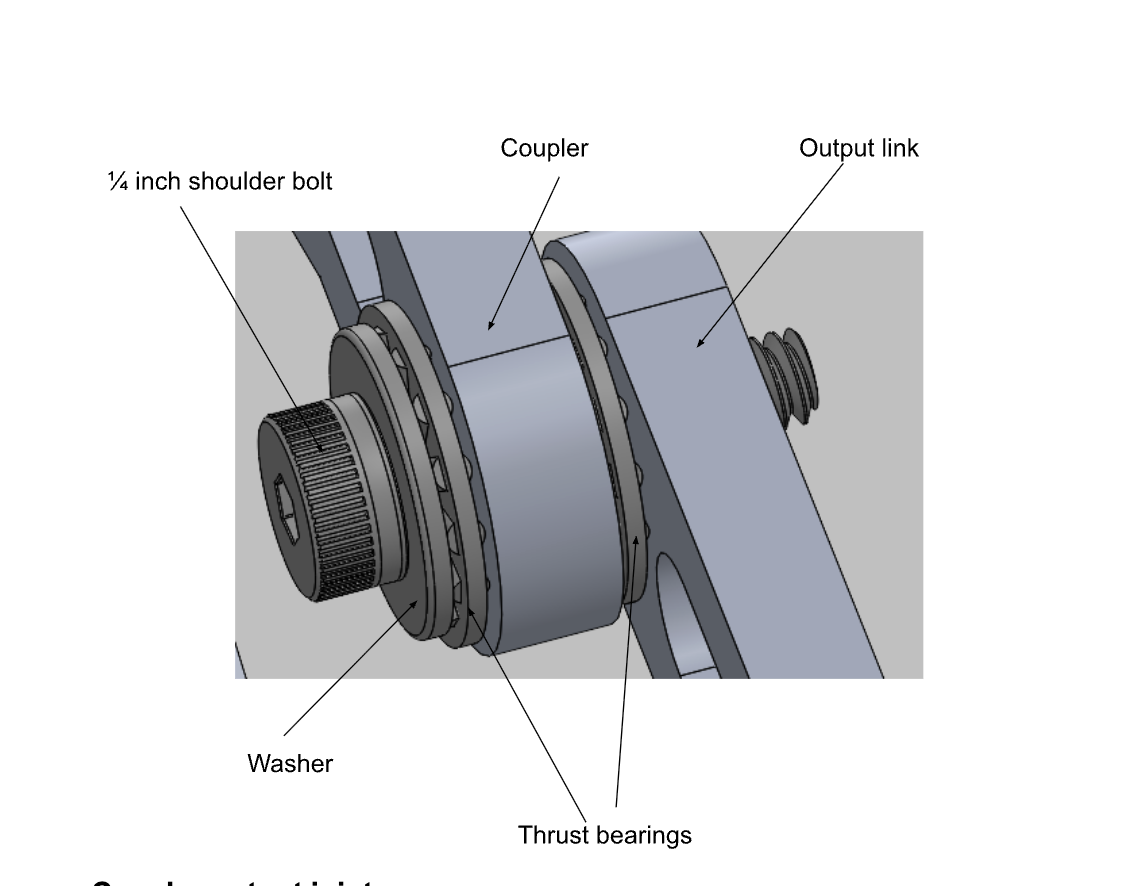

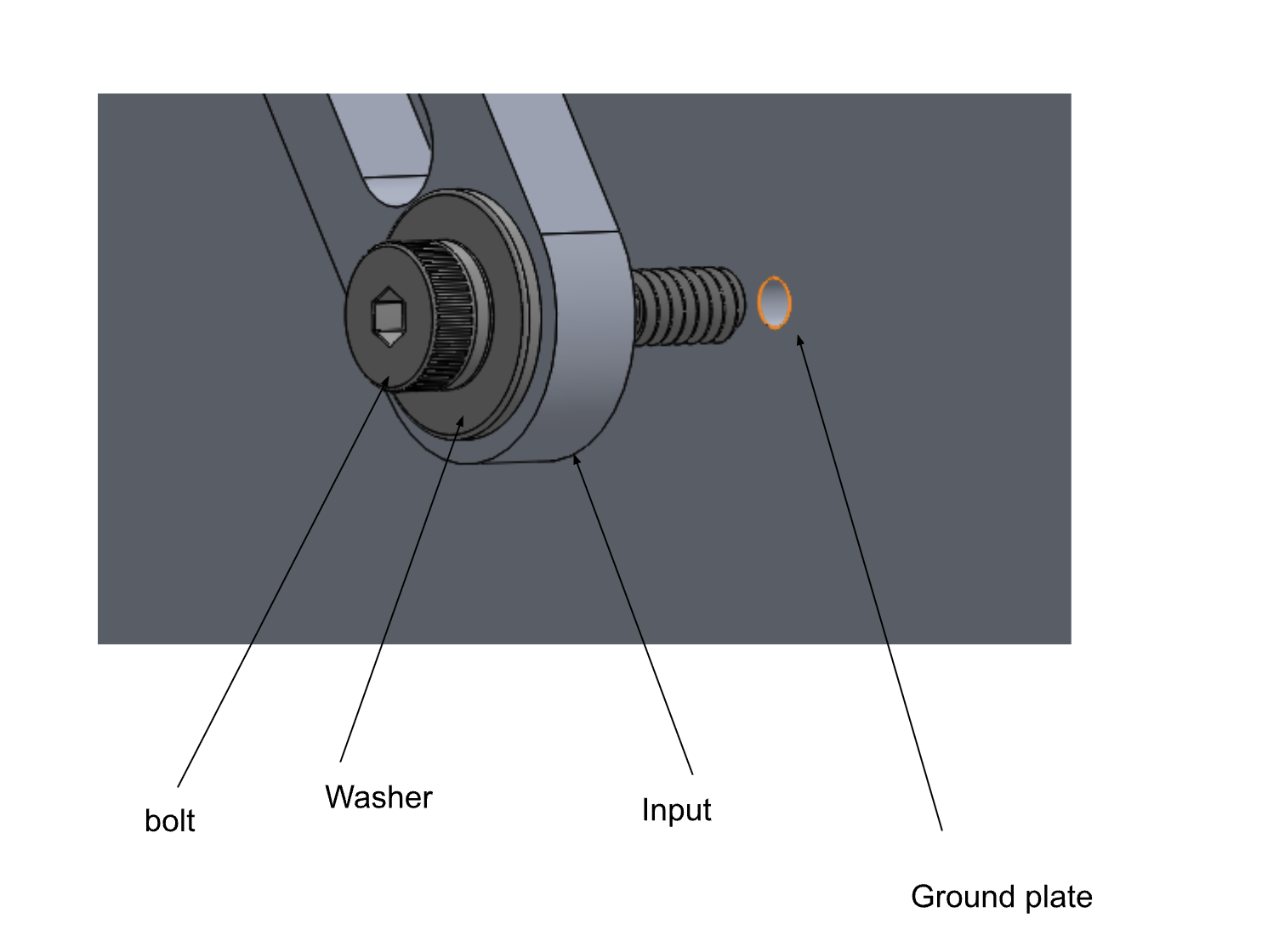

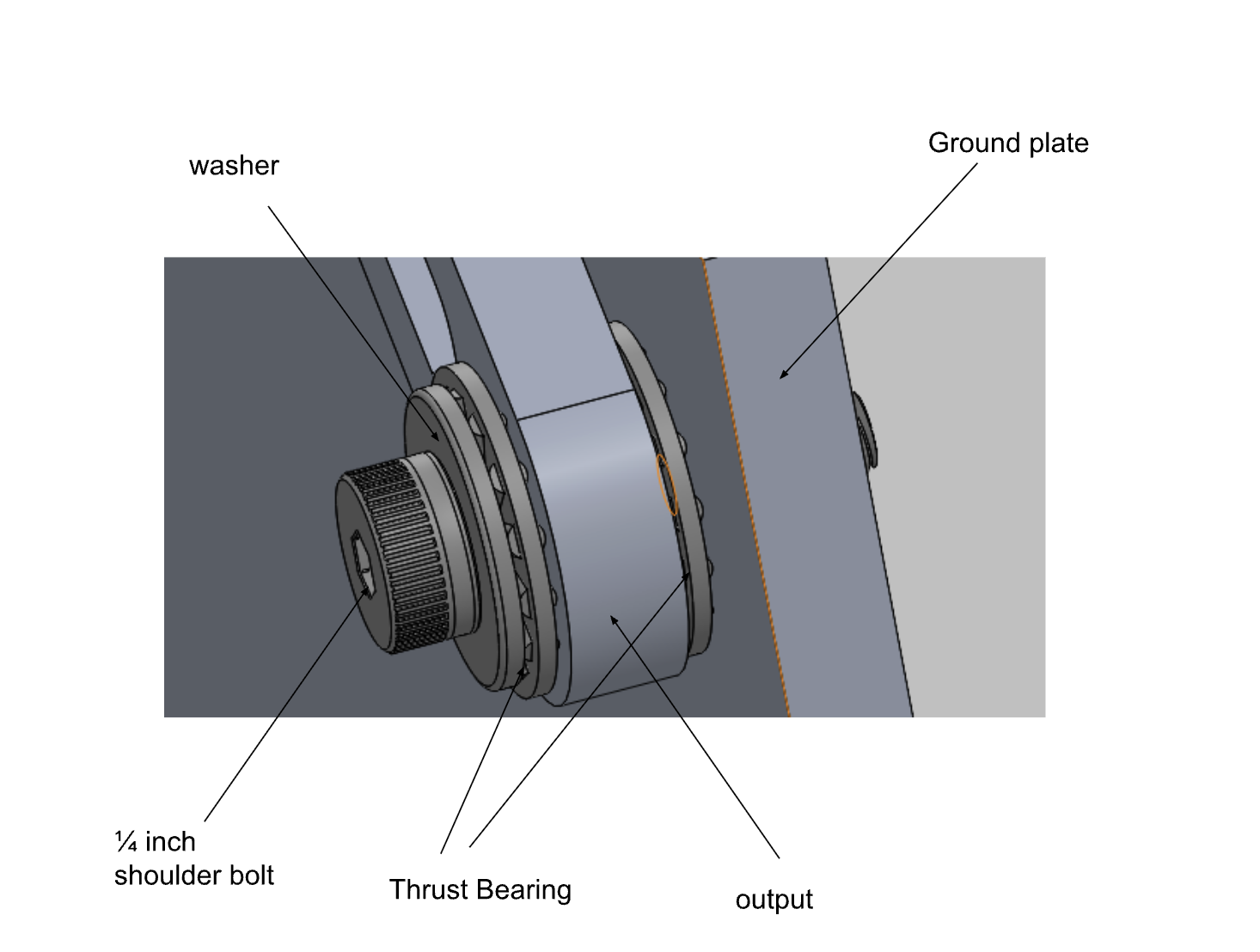

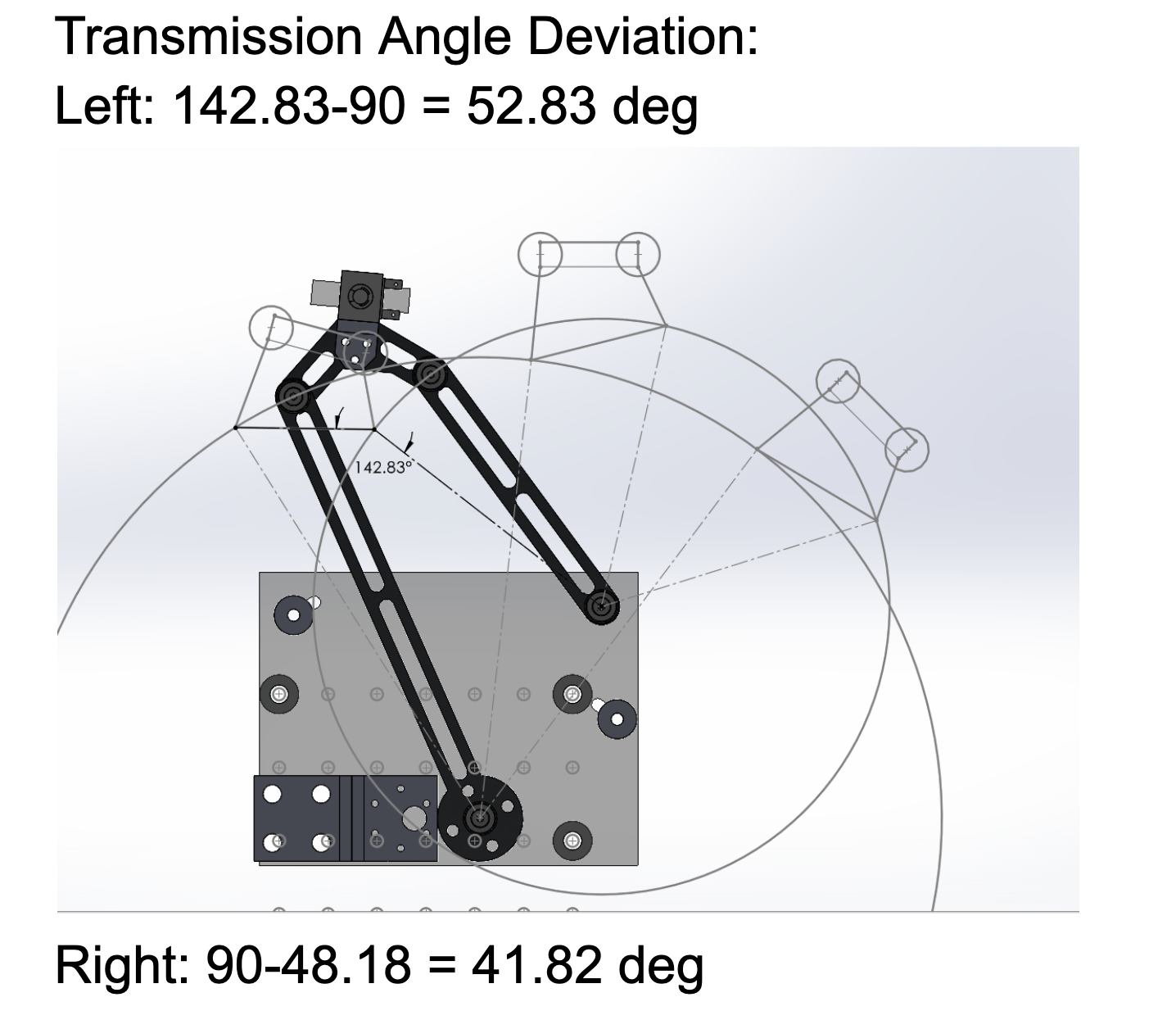

We designed a low inertia linkage mechanism in SolidWorks to position the coupler/solenoid device with sufficient speed and precision. We optimized linkage geometry to minimize our transmission angle deviation. We also kept in mind the volume of the entire mechanism, which was an added design constraint given to us by our professor. We made a gear transmission to optimize motor response and precision.

The system was powered and controlled using an Arduino that integrated a DC motor, H-bridge motor driver, encoder feedback, and fuse protection. The H-bridge enabled bidirectional motor control while the fuse provided overcurrent safety during rapid acceleration and stall conditions. A closed-loop position control was implemented using a PID controller, with gains tuned to achieve fast response, minimal overshoot, and accurate positioning. This integration of electronics made our linkage system a responsive and precise automated system capable of high speeds and repeatable motion.